| ACC106 | Accounting I | TBD | TBD | TBD |

| | This subject introduces the student to: a) what accounting information is required by a business concern to reflect clearly the operating results of the concern over its operating life; b) how this information is recorded in the various business records; c) how this information is used by, and meets the needs of both internal and external users; d) throughout the subject, students will be introduced to generally accepted accounting principles. |

| BAM101 | Introduction to Business Administration | TBD | TBD | TBD |

| | This subject is designed to provide students with an introduction to the Canadian business environment, business issues and functions, and the major forces at work in the global economy. It provides students with a perspective of business firms as integrated organizations composed of a number of specialized functions. |

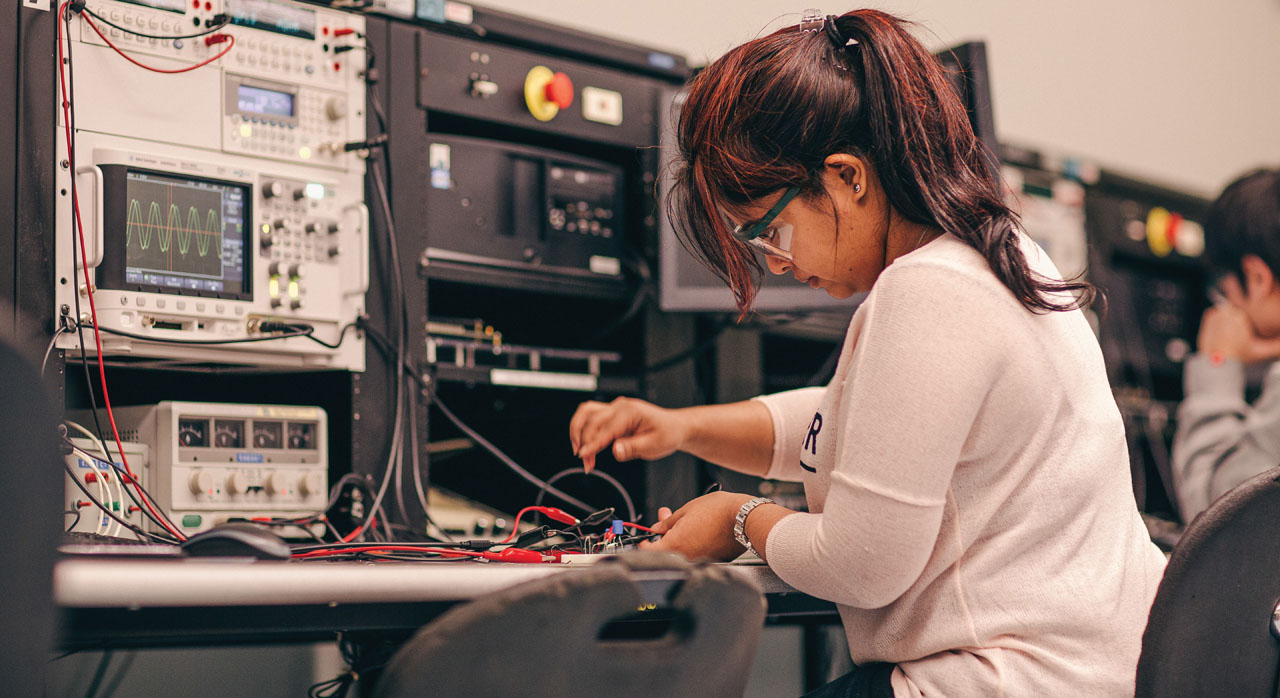

| HSI355 | Advanced Hardware and Software Interfacing | Hybrid | Hybrid | Hybrid |

| | This course explores the integration of electronics systems through methods of hardware interfacing and software programming. Students will build upon their knowledge of advanced circuits by examining the principles and applications for circuit designs containing more dynamic components, such as servo and stepper motors, miniature joysticks, ultrasonic sensors, accelerometers, speakers, number keypads, square LED matrices, RGB LEDs, 7-segment displays, and PIR motion detectors. Signal processing techniques such as PWM, streaming, and SPI communication will be used to interact with the devices. By first analyzing these circuits in the lectures and then constructing and troubleshooting them in the labs, students are able to investigate practical applications that contain both analog and digital inputs and outputs. The circuits will be modified to interface with a data acquisition unit programmed in C language. A lab project draws together the key elements from this course and previous courses and devices. Students emerge with comprehensive and practical hands-on experience in advanced electronic device integration, which provides support for subsequent studies. |

| MEC455 | Mechatronics Concepts | In-person | In-person | In-person |

| | This course covers the basics of mechanical components, fluid power, sensors, electrical components in a complex mechatronic system. Based upon a physical system, students will learn the essential functions and physical properties of mechanical, pneumatic and electrical/ electronic components and the roles they play within the system. They will also learn about mechanical components that lead and support the energy through a mechatronics system to increase efficiency and reduce wear and tear. Materials, lubrication requirements and surface properties will be examined. Technical documentation such as data sheets and specifications of mechanical elements and electrical drives will also be covered. By understanding the interworking of the complete system, students will learn and apply troubleshooting strategies to identify, localize and (where possible) correct malfunctions. Preventive maintenance of mechanical elements and electrical drives and safety issues within the system will be discussed. |

| MOM555 | Manufacturing Operations Management | In-person | In-person | In-person |

| | Mechatronics is an industry-focused, multi-skilled program which integrates the mechanical system, electrical/electronics, sensors, diagnostics and information technology in a holistic Mechatronics program. With Mechatronics, all of these disciplines are viewed together as a single entity, and more importantly, considered as a unity already during the design phase of the equipment, machines and industrial systems. In addition to teaching the technical knowledge, program content also stresses troubleshooting and system-based technical thinking via hands-on training. This cross-section discipline of applied engineering science helps to optimize the interaction between machinery construction and electronic systems and information technology so that the machines to be developed are harmonized as far as all of the important parameters are concerned even before the first, and in this case, the only prototype is built. The unification of the mechanical system, electronics and information technology in a simulation environment is of special significance. This unified simulation helps the mechanical design engineer to identify very early on just how the machine will subsequently behave. Shorter development times, higher quality and enhanced productivity are the advantages which are direct result of the mechatronics approach. |

| PCS455 | Process Control | Hybrid

In-person | Hybrid

In-person | Hybrid

In-person |

| | This course covers the basic principles for modelling and control simple mechanical, electrical, fluid and thermal systems. It gives a foundation from theoretical physics for considerations that they would likely encounter in real industrial control system situations. The fundamental concept of control system theory is covered. The controller modes used are P, PI, PD, and PID controllers, and On-Off controllers. Closed-loop system performance and stability such as transient response, steady-state error, rise time, settling time, gain margin and phase margin are examined. This course finishes with an introduction to various types of industrial controllers. |

| PPE655 | Engineering Ethics and Professional Practice | Hybrid

In-person | Hybrid

In-person | Hybrid

In-person |

| ROB555 | Robotics Basics | In-person | In-person | In-person |

| | This course is designed for the robot programmers and start-up personnel. It covers the basics of robotics technology, robotics applications and related safety and standards. Students will learn function and safe use of a robotics system. Students will reliably demonstrate the ability to configure, modify, maintain, and integrate robotics systems to ensure that they function according to specifications. They will also learn how to integrate robotic systems with other automation equipment through discrete and/or analog I/O and real-time networking. Focus will be paid to safety and functions of the safety interface while working with robotics systems. Technical documentation related to manipulator, controller, and power subsystems of the robotic systems, such as schematics, data sheets and specifications will be also covered. By understanding the interworking of the complete system, students will learn and apply troubleshooting strategies to identify, localize and (where possible) correct malfunctions. Preventive maintenance and safety issues within the system will be discussed. |

| TIA555 | Totally Integrated Automation | In-person | In-person | In-person |

| | This course covers the advanced automation topics and PC based controls. The first part of the course covers advanced PLC functions and communication networks. Basics of various controls communications networks are also described. The course includes practical exercises setting up PLC to HMI communications. It also covers troubleshooting techniques and practical exercises debugging and modifying existing PLC programs in industrial environment. The course describes procedures and parameters of setting up drives and motors. By understanding the interaction of the complete control system, students will learn and apply troubleshooting strategies to identify, localize and (where possible) correct malfunctions. In the second part of the course, focus is on PC based control systems. The course also covers basics of IEC 6131-3 programming standard. This course is a requirement for the Siemens Mechatronics Level II Certification. |